Galvanized Steel vs Stainless Steel

Several types of steel exist in the manufacturing market, two of the most common being galvanized and stainless steel. Steel is created from coal or ore and then when treated becomes used in a variety of applications. Both galvanized steel and stainless steel are known for being strong and durable. They are both used in construction, but in different applications. Galvanized steel and stainless steel look very similar, but differ in cost, composition and weight. Galvanized vs stainless steel corrosion resistance is a major consideration for choosing to work with either of these metals.

Contact Newone, Inc to find out more about galvanized steel today!

What are the Main Differences between Galvanized Steel and Stainless Steel?

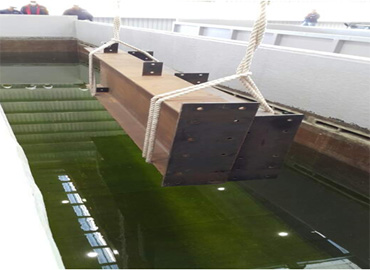

Galvanized steel is made when regular carbon steel is coated with a thin layer of zinc. This coating is created with one of two methods, electrogalvanizing or hot dipping. This zinc layer helps to prevent corrosion and rust. Galvanized steel costs less than stainless steel, however, it is weaker.

Stainless steel is created by mixing chromium with carbon steel while in its molten state. After mixing, the steel is left to cool and harden, then treated to remove surface impurities with acid. The chromium helps to prevent rust and corrosion. Stainless steel is stronger than galvanized steel, however, it costs more.

Both types of steel can theoretically be used in the same applications, but practically, they are best used in different applications.

What about Galvanized vs Stainless Steel Outdoor Applications?

When considering outdoor applications, both galvanized and stainless steel have good, valid uses. Understanding how they differ is key.

Galvanized steel’s zinc protective coating is ideal for outdoor applications that are near saltwater. The zinc layer prevents the saltwater from coming into contact with the carbon steel, saving the steel from the harmful effects of the saltwater. However, in other outdoor applications, galvanized steel will require more upkeep over long periods of time as the zinc layer will eventually corrode.

Stainless steel’s composition of different types of metals does create a long lasting effectiveness against the elements. Additionally, unlike galvanized steel, stainless steel doesn’t flake over time, keeping the original look for years, unless exposed to salt. Stainless steel is much more expensive upfront, however. Another important problem to take note of is that stainless steel should not be used anywhere that it could rub against another piece of stainless steel.

What is the Difference in Galvanized Steel vs Stainless Steel Cost?

As mentioned before, the cost is significantly different between galvanized and stainless steel. Depending on the project, the upfront capital available, and length of time the steel will need to last, all come together to determine which steel is more appropriate.

Generally, galvanized steel costs less than a dollar per pound, whereas stainless steel can cost up to five times more. That can be a hefty upfront cost.

What is the Difference in Galvanized Steel vs Stainless Steel Weight?

Galvanized steel is a type of metal with a thin layer of another compound, resulting in a much lighter material. Stainless steel is a combination of several metals making it much heavier. Why does it matter the weight difference? Transportation costs and malleability. Transporting a lighter weight steel, such as galvanized is going to be much cheaper than a heavier steel, such as stainless. Also, the lighter weight galvanized steel is much more malleable than the heavier stainless option.

Newone Inc has provided quality galvanized steel to customers for over 30 years. This highly equipped supplier manufactures top quality galvanized steel made through the hot dip galvanizing process. Contact Newone Inc today to learn more!