Hot dip Galvanizing Services

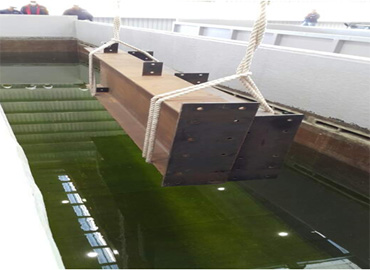

Our experience and specialty is the hot dip galvanizing(hdg) and we have more than 30 years of experience. This process consists in immerge black steel material in a kettle filled with molted zinc, causing a metallurgical reaction that formes an alloy between both metals, resulting in a coating that will allow full protection against any environment.

In addition to having traveling cranes, we also have a 2nd level of hoists that allows the best quality at a better time. Regarding to our capacity: production capacity is above 2,000 tons per month. Kettle dimension is 12.0 m x 2.0 m x 3.5 m

Within our hot dip galvanizing service, we have the ability to galvanize everything you need such as street-lights, traffic-lights, guardrails, steel pipe of all sizes, structures (beams, angles, hss, channels, wide flanges), transmission towers, etc.

Service categories

Galvanizing services

We provide galvanizing services for all kinds of metal. please contact us for details.

- Galvanized Guardrail

- Galvanized Traffic - Light

- Galvanized Steel Tower

- Galvanized Cable Tray

- Galvanized Pipe

- Any materials

Service categories

Quality Assurance

“Quality Assurance” is our way to prevent any kind of mistakes or defects in our manufacturing processes. Indeed, it allows us to detect problems so we could deliver solutions instead and it makes us offer to our customers the best service.

Customer Satisfaction

We achieved 0% complaints from our clients because we make sure they are satisfied with the results.

Additional Information

The first maintenance of hdg material would depend on its environmental conditions. In case hdg material stays in tropical marine environment, its first maintenance should be make after 58 to 60 years aproximately.