This type of coating is one of the most efficient and well-documented methods of surface protecting treatment. The hot dipping Galvanized Steel is a very popular metal because of its durability and applicability, the process is carried out by skilled operatives to ensure high quality and standards maintain.

The galvanized process steps are prepared based on specific requirements from our customers. First there are four tanks full of acid solution, that removes all impurities like stains, rust or inorganic residues from black steel materials as an effective surface treatment before HDG. Next, the rinsing, that consists of washing materials in a water bath.

It is very important because every remaining and acid residues over the material surface are removed before they start the next step, which is flux solution, the tank contains chemical ingredients which allow a perfect coating results due to its combination of ammonium zinc chlorides in order to remove all oxide film which forms from acid washing tanks.

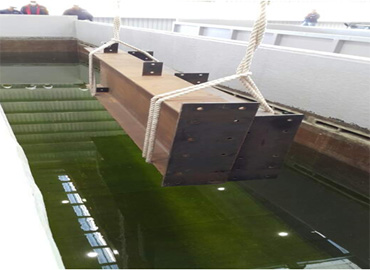

The Hot Dip Galvanizing is a process known for Zinc Coating, this tank is called a Zinc Kettle too that contains molten zinc at about 450 °C (842 °F) where black steel is immersed for a determined time to finally get a coating result. And lastly, cooling, the final two tanks. The first one contains purified water in order to use it as quench baths for galvanized materials to drop their temperature, and the second one contains passivated solution which would prevent white rust and it would give a bright coating appearance for more time. We are 1# company that specializes in galvanizing technologies and its products, and by this we can assure our clients the most efficient production method, >the less it costs to execute.

Learn more about us and the services we provide by visiting our website at: >www.newoneinc.com